The fitting hole pattern on the Equipment Towers are cleverly designed with flexibility in mind. This eliminates the need for additional connecting parts to attach equipment such as junction boxes. This helps to simplify logistics, reduce weight and reduces installation time.

Øglænd System Equipment Towers are supplied in standard 2m, 2.5m, and 3m heights. Where shorter heights are required, we have a supplementary range of sturdy Instrument Stands available which benefits from the same innovative design.

Standardised design

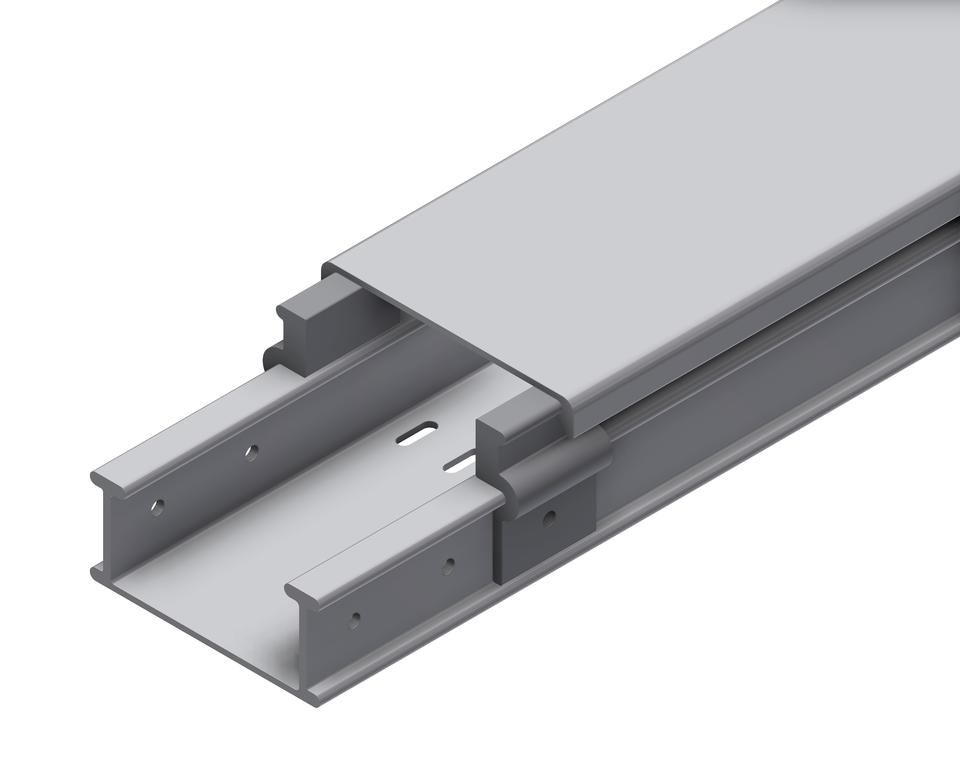

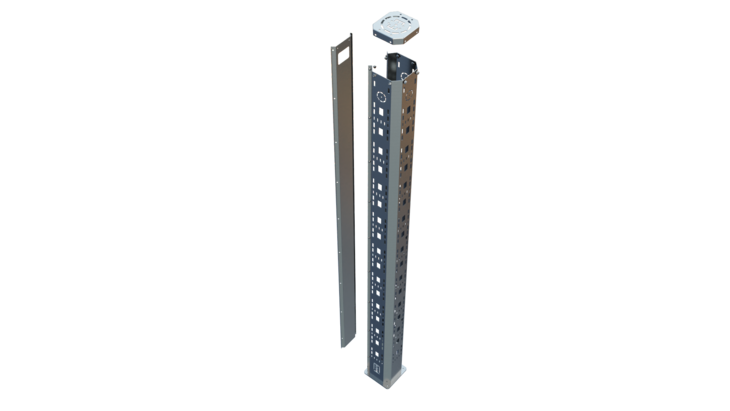

Our Equipment Towers have a stable construction and consists of just three main parts; body, top plate and back plate. You can choose between three different heights:

|

Equipment Tower OET-OCT-2000 SS |

Equipment Tower OET-OCT-2500 SS |

Equipment Tower OET-OCT-3000 SS |

| 2m | 2.5m | 3m |

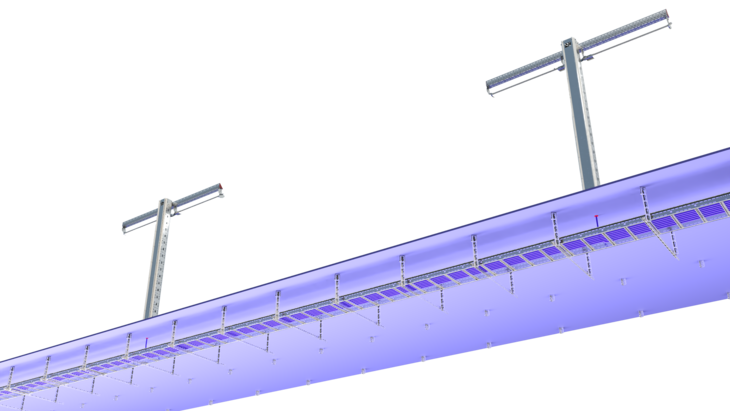

Access and routing possibilities

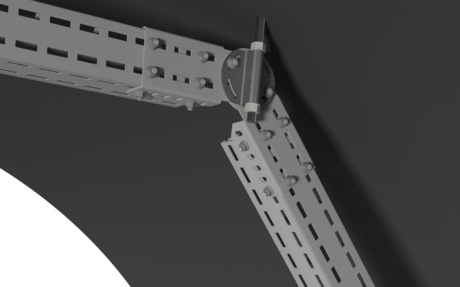

The flexible hole pattern makes it incredibly easy to route cables directly on the column’s three sides. The back panel may also be removed to access the inside for easier installation of equipment and cables. For routing from the side, a steel hinge near the base is simply bent to create both an aperture for cable, and an attachment splice for cable tray without any additional brackets required. Furthermore, it is possible to route from below, as the stand is designed with access from the base.

Welding base plates

The Equipment Tower fits the bolted doubling plate with 4x M10 threaded holes. However, if you wish to route cables through the floor there is a plate with integrated Hilti MCT cable transit available too.

Design features

"All in one" design

Each equipment tower consists of only three main parts, which are assembled with M10 and M6 self-locking, anti-vibration fasteners (included).

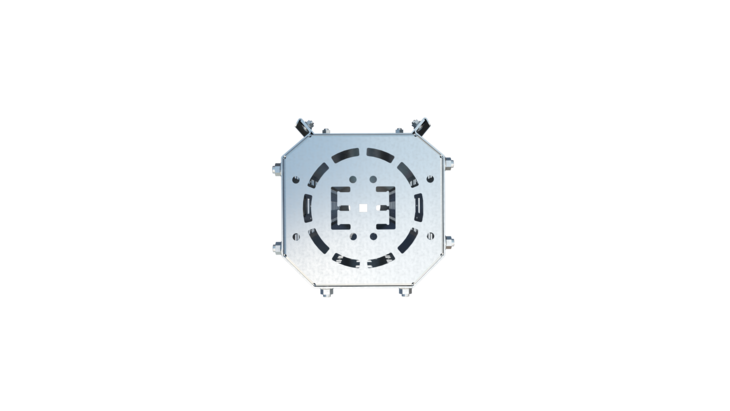

Flexible hole pattern

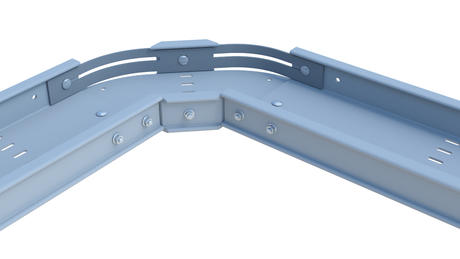

The flexible hole pattern eliminates the need for any extra brackets and simplifies logistics. Equipment can be installed directly to the Equipment Tower. Each side and the top can also be fitted with cable tray, both for safe routing of cable, and for tubing. Oglaend System’s ETIN™ tubing clamp solutions fit directly onto the body of the stand, significantly reducing parts and installation time.

PRODUCT FUNCTIONALITY AND DETAIL

- Available in 2.0 m, 2.5 m and 3.0 m heights

- Fits most commonly used equipment on body without using extra brackets

- Flexible hole pattern

- Compatible with ETIN™ tubing clamps

- Compatible with SPB cable tray

- Compatible with MCT cable transit doubling plate

- Removeable back plate

PRODUCT ADVANTAGES

- Stable construction

- Eliminates need for bespoke design, reducing engineering time

- Fits equipment directly on body

- Low weight

- Possible routing on outside, inside and through the bottom

- Support for multiple applications such as; floodlights, line detectors, loudspeakers, CCTV cameras etc.